News

- Industry news

Industry news

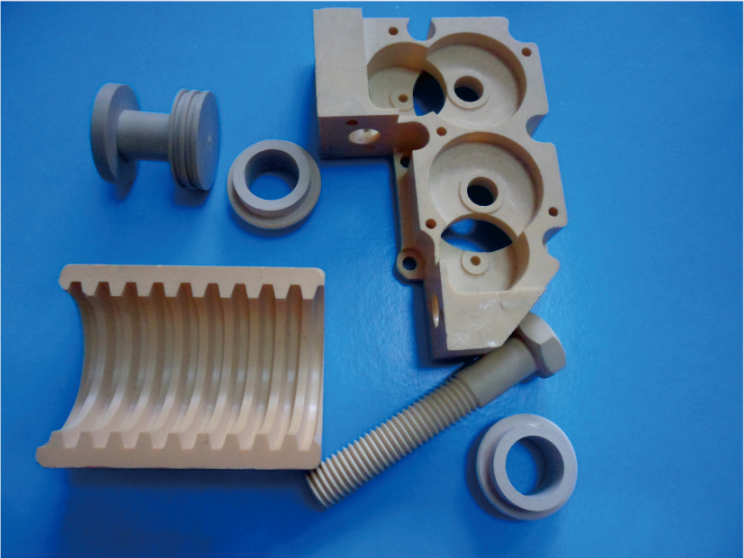

Application and popularization of special engineering plastic products

Special engineering plastic products refer to a class of special engineering plastic products with high comprehensive performance and long-term use temperature above 150 ° C. They mainly include polyphenylene sulfide (PPS), polyimide (PI), and polyetheretherketone (PEEK). ), Liquid crystal polymer (LCP) and polysulfone (PSF). Special engineering plastics have unique and excellent physical properties, and are mainly used in high-tech fields such as electronics, electrical and special industries.

Polyphenylene sulfide (PPS): a new type of high-performance thermoplastic resin, which has the advantages of high mechanical strength, high temperature resistance, high flame resistance, and strong chemical resistance; it is hard and brittle, high crystallinity, flame resistance, and thermal stability Good performance, high mechanical strength, excellent electrical properties, etc. PPS is one of the most heat resistant varieties in engineering plastics. The heat distortion temperature is generally greater than 260 degrees, the chemical resistance is second only to polytetrafluoroethylene, and the fluidity is second only to nylon. In addition, it also has the advantages of small molding shrinkage (about 0.08%), low water absorption (about 0.02%), good fire resistance, good vibration fatigue resistance, etc., specific gravity: 1.36 g / cm3 Temperature: 300-330 ° C.

PPS is widely used in electronics, automobile industry, machinery industry, chemical industry and other fields.

Polyimide (PI): An aromatic heterocyclic polymer compound with an imide chain in the molecular structure, and its English name is Polyimide. Its density is 1.35, non-toxic and flame retardant, and can be sterilized at high temperature. Polyimide (PI) is a super engineering plastic with excellent comprehensive properties (long-term work at 250 ° C), and has excellent mechanical properties, thermal dimensional stability, dielectric properties, wear resistance, weather resistance, The properties of wave permeability and self-lubrication are called "problems to solve problems".

PI is widely used in parts with low coefficient of friction and wear resistance under high speed and high pressure, parts with excellent resistance to creep or plastic deformation, parts with excellent self-lubrication or oil lubrication performance, liquid seals under high temperature and pressure Parts, parts with high resistance to bending, stretching and high impact resistance, parts with corrosion resistance, radiation resistance and rust resistance, parts with a long-term use temperature of more than 300 ° C and short-term 400-450 ° C, high temperature (Over 260 ℃) Structural adhesives (modified epoxy resin, modified phenolic resin, modified silicone adhesive, etc. where the high temperature does not exceed 260 ℃), for microelectronic packaging, stress buffer protective coating, multilayer interconnection Structural interlayer insulation, dielectric film, chip surface passivation, etc.

Polyetheretherketone (PEEK): A crystalline aromatic super heat-resistant thermoplastic. Polyetheretherketone is a high performance, wide range of applications and practical plastics developed according to the requirements for use in harsh environments. The softening point is 334 ° C and the glass transition temperature is 143 ° C. The benzene ring has a carbonyl group hook, which has high physical and chemical properties and can be hot melt formed.

PEEK is widely used in aerospace, electronics, medical equipment, energy and power, petroleum exploration and extraction industry, machinery industry, automobile and other industries.

Liquid crystal polymers (LCP): A new class of polymers with outstanding properties. LCP is a wide range of materials: lyotropic liquid crystal: needs to be processed in solution; thermotropic liquid crystal: can be processed in the molten state. It has high temperature resistance, excellent electrical insulation properties, outstanding corrosion resistance, and excellent flame retardancy.

Electronic and electrical is the main market of LCP: Surface and assembly welding technology of electronic and electrical has high requirements on the dimensional stability and heat resistance of materials. LCP: printed circuit boards, satellite electronic components, jet engine parts, automotive mechanical parts, In the medical field, it replaces epoxy resin as the encapsulation material of the coil bobbin, and replaces ceramics as the filling material in the separation tower for chemical industry, as the optical fiber cable connector head cover and high-strength components.

Polysulfone (PSF): a thermoplastic resin containing links in the molecular main chain. It is a light brown transparent amorphous resin. Two kinds of ether sulfone. It has excellent heat resistance, excellent mechanical properties, high rigidity, high strength, abrasion resistance, hydrolysis resistance, good chemical stability, and excellent electrical insulation properties.

PSF is widely used in the fields of electronics and electronics, automotive, aviation, kitchen supplies, sanitation, medical, daily necessities, industrial applications.