News

- Industry news

Industry news

Seals things you need to know!!

01

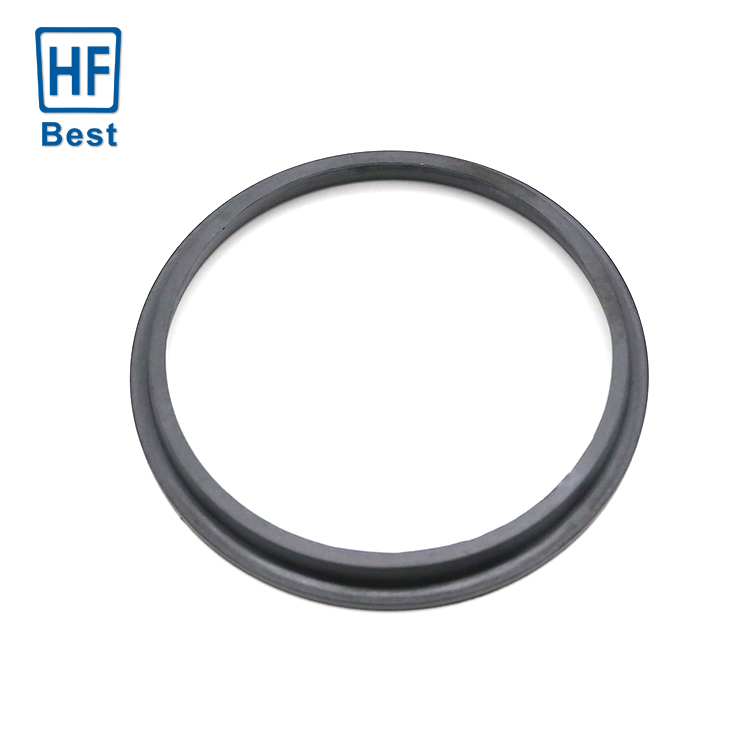

What are seals?

Seals are materials or parts that prevent fluid or solid particles from leaking from adjacent joint surfaces and prevent external impurities such as dust and water from intruding into the internal parts of machinery and equipment. The sealing parts should be stored at room temperature below 30℃ to avoid high-temperature aging of the sealing parts.

02

What are the classifications of sealing?

Sealing can be divided into two categories: static sealing and dynamic sealing between relatively static joint surfaces. Static seal is mainly a little seal, rubber seal and contact seal three categories.

According to the working pressure, static seal can be divided into middle and low pressure static seal and high pressure static seal. Medium and low pressure static seal is usually made of soft material and wide gasket, while high pressure static seal is made of hard material and metal gasket with narrow contact width.

Dynamic seal can be divided into rotary seal and reciprocating seal two basic types.

According to the sealing parts and their relative movement of contact, can be divided into contact seal and non-contact seal. Generally speaking, the sealing performance of contact seal is good, but limited by friction and wear, suitable for the occasion of low linear velocity sealing surface. The non-contact seal has poor sealing performance and is suitable for higher speed occasions.

03

What are the types and uses of sealing materials?

Sealing materials should meet the requirements of sealing function. As the sealing medium is different, and the working conditions of the equipment are different, the sealing materials are required to have different adaptability. Requirements for sealing materials are generally:

1) The material has good compactness and is not easy to leak medium;

2) Appropriate mechanical strength and hardness;

3) Good compressibility and resilience, small permanent deformation;

4) no softening, no decomposition at high temperature, no hardening, no brittle crack at low temperature;

5) Good corrosion resistance, in acid, alkali, oil and other media can work for a long time, its volume and hardness change is small, and does not adhere to the metal surface;

6) Small friction coefficient and good wear resistance;

7) Softness combined with sealing surface;

8) Good aging resistance and durability;

9) Convenient processing and manufacturing, cheap price, easy materials.

04

Performance index for determining the quality of sealing materials

1. Tensile properties

Tensile properties are the first properties to be considered for sealing materials, including tensile strength, fixed elongation stress, elongation at break and permanent deformation at break. Tensile strength is the maximum stress of specimen stretching to fracture. Constant elongation stress (constant elongation modulus) is the stress reached at specified elongation. Elongation is the deformation caused by the specified tensile force of the specimen, the ratio of the increment of elongation to the original length. Elongation at break is the elongation of specimen at break. Tensile permanent deformation is the residual deformation between the lines after tensile fracture.

2. The hardness

Hardness represents the ability of sealing material to resist external pressure, and is also one of the basic properties of sealing material. The hardness of the material is related to other properties to a certain extent. The higher the hardness, the greater the strength, the smaller the elongation, the better the wear resistance, and the worse the low temperature resistance.

3. Compression performance

Rubber seals are usually in a state of compression, due to the viscoelasticity of rubber material, the pressure will decrease with time when compression, manifested as compression stress relaxation; After removing the pressure, it cannot return to its original shape, showing permanent deformation under compression. This phenomenon is more obvious in high temperature and oil medium, which is directly related to the durability of sealing ability of sealing products.

4. Low temperature performance

Used to measure the low temperature characteristics of rubber seals, the following two methods to test the low temperature performance:

(1) Low temperature retraction temperature: stretch the sealing material to a certain length, and then fix it, cool it quickly to below freezing temperature, loosen the test piece after reaching equilibrium, and heat up at a certain speed, and record the temperature of 10%, 30%, 50% and 70% retraction in TR10, TR30, TR50 and TR70 respectively. The material standard is TR10, which is related to the brittle temperature of rubber.

(2) low temperature flexure: after the sample is frozen to the specified time at the specified low temperature, it is reciprocated and bent at the specified Angle to investigate the advantages and disadvantages of the sealing ability after repeated action of dynamic load at low temperature.

5. Oil resistance or medium resistance

Sealing materials in addition to contact with petroleum base, double ester, silicone grease oil, in the chemical industry sometimes also contact with acid, alkali and other corrosive media. In addition to corrosion in these media, at high temperature will also lead to expansion and strength reduction, the reduction of hardness; At the same time, plasticizer and soluble substances in the sealing material are pulled out, resulting in mass reduction, volume reduction and leakage. In general, at a certain temperature, the quality, volume, strength, elongation and hardness are determined after immersion in the medium to evaluate the advantages and disadvantages of oil resistance or medium resistance of sealing materials.

6. Aging resistance

Sealing materials by oxygen, ozone, heat, light, moisture, mechanical stress will cause performance deterioration, known as the aging of sealing materials. Aging resistance (also known as weather resistance) can be used after aging style strength, elongation, hardness changes to express, the smaller the change rate of aging resistance is better. Note: weatherability refers to plastic products due to the influence of sunlight, temperature change, wind and rain and other external conditions, and the appearance of fading, discoloration, cracking, powder and strength decline and a series of aging phenomenon. Among them, ultraviolet radiation is the key factor to promote plastic aging.