News

- Industry news

Industry news

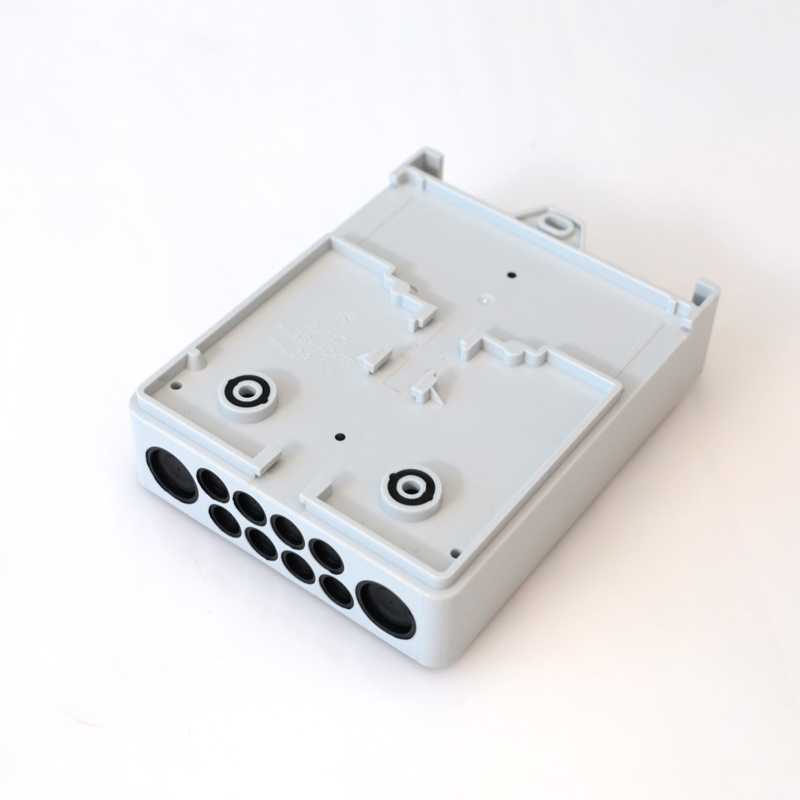

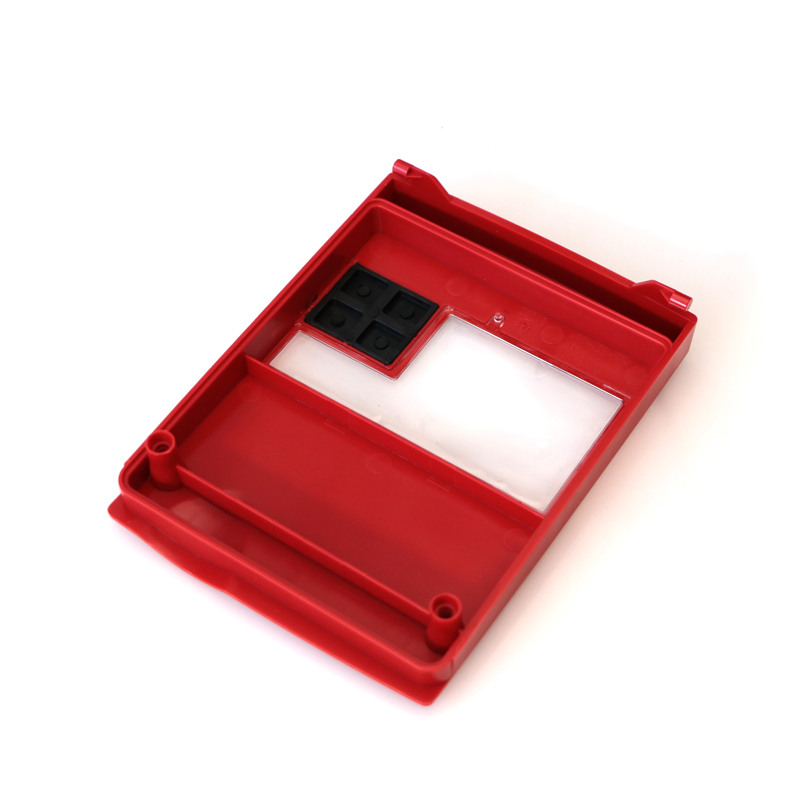

Plastic science - secondary injection molding

The processing method of secondary injection molding

1、Multiple injection molding

If the structure of the covering material allows, multiple injection molding is a good medical device processing method. The technique requires special injection molding machines equipped with multiple cylinders to inject different resins into a single injection mold. The cylinders should be placed side by side or in an L-shape, with one or more injection points to inject the resin into the mold. When the same injection point is used, it is called co-plastic, and the composite parts produced are core resin materials covered by an outer layer. When multiple injection points are used, called secondary injection molding, one material is molded on top of another material to produce a multilayer structure.

2、Embedded injection molding

To produce products such as fully covered injection handles, it is necessary to use embedded injection molding. In order to achieve full coverage, the substrate

must be removed from the original mold cavity and put into another mold core and mold cavity in order to inject the covering material. During this process, another mold should be run simultaneously on the same or another injection molding machine of a different size (depending on the size of the injection part). Usually the substrate is much larger than the covering material and may need to be preheated so that the surface temperature is close to the melting point of the covering material for optimal bonding strength.

Secondary injection molding coating machining process

1. Add ingredients after baking

The granular or powdered plastic is added or sucked into the vertical injection molding machine hopper with the suction machine, and then heated with the plunger and screw into the barrel.

2. Plasticize

The process in which the plastic is heated, compacted and dissolved in the barrel of the machine, from loose powdery particles or granular solids to continuous homogenized melt.

3. Fill mold

The plasticized plastic melt under the plunger or screw of the machine has a certain pressure and speed through the nozzle and the pouring system of the mold into and full of the mold cavity, this stage is called mold filling.

4. Maintain pressure

After the end of the mold filling, the plunger or screw push, the melt still maintains pressure to fill, so that the molten material in the cylinder continues to enter the cavity, has been added to the shrinkage of the plastic in the cavity, the pressure holding time should be appropriate, too long the pressure holding time is easy to make the plastic part produce internal stress, causing the injection molding part deformation or cracking.

5. Reverse flow

After the end of the pressure holding, the plunger or screw moves up, and the molten pressure in the mold cavity is relieved. At this time, the molten pressure in the mold cavity will be higher than the pressure in front of the gate. If the gate has not frozen at this time, the molten material in the mold cavity will flow back through the pouring system, causing the defects such as shrinkage, deformation and loose texture of the injected parts. If the gate has been frozen when the injection pressure is withdrawn, the backflow phenomenon will not occur, it can be seen that whether the backflow occurs is related to the pressure holding time.

6. Cool down

The cooling process of plastic injection parts in the mold refers to the whole process from the complete freezing of the plastic melt at the gate to the release of the injection parts from the mold cavity. At this stage, neither feeding nor backflow continues, and the plastic in the cavity continues to cool, harden and shape.

7. Release mold

The plastic parts can be opened after cooling, and under the action of the injection mechanism, the plastic products are ejected to complete.

Guangzhou Best Rubber & Plastic Co., Ltd. has more than 20 years of experience in secondary injection molding, with more than 2,000 square meters of physical processing plants, but also has professional production and processing equipment, as well as professional design team, can provide customers with satisfactory products and services.

The difference between two-color injection molding and secondary injection molding

1.Two-color injection molding, also known as two-color injection molding, is the two kinds of plastic materials in the same injection molding machine injection molding, divided into two molding, but the product only out of the mold once the mold, usually completed by a set of molds, and the need for a special two-color injection molding machine. The same after mold, different before mold, high production efficiency, good product quality, suitable for mass production.

2.Secondary injection molding is also called plastic injection molding, is not necessarily two kinds of plastic materials in the same injection molding machine injection molding, divided into two molding; After the product is removed from a set of molds, it is placed into another set of molds for secondary injection molding. Therefore, in general, this molding process is usually completed by two sets of molds, without the need for a special two-color injection molding machine. Secondary injection molding is the first part of the product injection completed out, and then put into another injection molding machine injection molding, efficiency will be slower, the cost will be higher, suitable for small batch production.

Factors to pay attention to when selecting materials for secondary injection molding

1.Chemical corrosion resistance (in line with cleaning and other operating requirements).

2. Flame retardant (in line with environmental protection and other requirements). Eco-label is a sign that a product meets environmental and social standards.

3.Abrasion resistance (so as not to sag or fall off).

4. Shore hardness (in line with soft or other requirements).

5.Medical specifications (FDA, USP Class VI, ISO10993 and biocompatibility requirements).

6. Sterilization types (steam, gamma rays, etc.).

7.Impact resistance (meet the structural requirements).

8.Melting point (meet the application temperature requirements, will not soften or deformation).

9.Bonding mode (mechanical interlocking effect is formed when two materials do not match, and chemical bonding is formed when two materials match).