News

- Industry news

Industry news

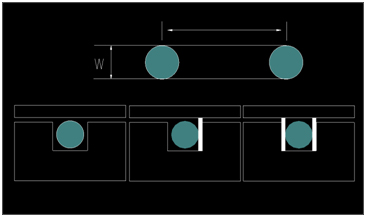

Application and popularization of O-ring technology

Suitable for sealing of hydraulic and pneumatic components and various mechanical equipment under static or moving conditions.

Technical Parameters:

1. Working temperature: -60 ℃ ± 220 ℃

2. Working pressure: without retaining ring ≤ 40 kg / cm3 (depending on the material of the O-ring)

Plus retaining ring ≤250 kg / cm3

Perfluoro rubber O-ring

Perfluoro rubber (FFKM) is a monomeric terpolymer, in which all hydrogen atoms are replaced by fluorine atoms. Since there are no hydrogen atoms in the molecular chain, the chemical resistance and heat resistance of perfluoro rubber are sharp. Enhanced. This cross-linked molecular chain makes the perfluororubber have the elasticity and sealing force of synthetic rubber, and has the chemical inertness and thermal stability of polytetrafluoroethylene (PTFE). Perfluoro rubber has excellent airtightness (resistance to vacuum (1.33X10-8pa) and high cleanliness and ion resistance, extremely wide allowable working temperature range _-25 ℃-+ 325 ℃).

Because of its excellent reliability and long service life, it is widely used in chemical processing, pharmaceutical and food industry, oil and gas industry, hydrocarbon processing industry, semiconductor and manufacturing industry, paint, printing and coating industry, aerospace industry , Power industry.

Polytetrafluoroethylene O-ring

Polytetrafluoroethylene is also called PTFE; Teflon; Teflon; Teflon; Teflon; 4F; King of Plastics.

It has non-stickiness, excellent heat resistance and low temperature resistance. It can work at freezing temperature without embrittlement and does not melt at high temperature. Sliding, moisture resistance, abrasion resistance, corrosion resistance, can protect parts from any kind of chemical corrosion.

Nitrile rubber O-ring

Nitrile rubber has good oil resistance, high wear resistance, good heat resistance and strong adhesion. Its disadvantages are poor low temperature resistance, poor ozone resistance, poor insulation performance, and slightly lower elasticity. It can be used for a long time in air at 120 ° C or in oil at 150 ° C. In addition, it also has good water resistance, air tightness and excellent adhesion properties.

Fluoroplastic O-ring

Fluorine rubber is a well-known high-performance rubber, especially with excellent high temperature resistance, ozone resistance, weather resistance, hydrogen resistance, mineral oil resistance, fuel oil resistance, hydraulic oil resistance, aromatic resistance and many organic solvents and chemicals Nature. Cold resistance is poor.

Widely used in aerospace, aviation, automotive, petroleum and household appliances

Hydrogenated nitrile rubber O-ring

Hydrogenated nitrile rubber O-ring Hydrogenated nitrile rubber (HNBR) is a saturated elastomer obtained by specific hydrogenation of nitrile rubber. Hydrogenated nitrile rubber has good oil resistance (good resistance to fuel oil, lubricating oil and aromatic solvents); and because of its highly saturated structure, it has good heat resistance and good chemical resistance (to Freon, acid, and alkali have good resistance), good ozone resistance, high resistance to compression and permanent deformation; meanwhile, hydrogenated nitrile rubber also has high strength, good tear resistance and wear resistance.

O-rings

In physics, silicone rubber is a kind of saturated non-polar rubber based on the silicon element derived from quartz, and formed by the adhesion of silicon atoms to side chains such as methyl and vinyl. Add different side chains to achieve different important attributes. After the formulation, the tensile strength can reach 500PSI and the resistance to 88LBS.